Understanding motor performance is key for industries that need efficient and reliable machines. At the core is motor flow, which affects a motor’s efficiency and output. We’ll look into motor flow, its importance, and what influences it.

Key Takeaways

- Understand the concept of motor flow and its impact on motor performance

- Discover the role of FLA (Full Load Amps) in motor efficiency

- Explore the factors that affect motor flow, including design and operating conditions

- Learn how to measure and optimize motor flow for improved performance

- Explore the applications of motor flow in various industrial settings

What is Motor Flow?

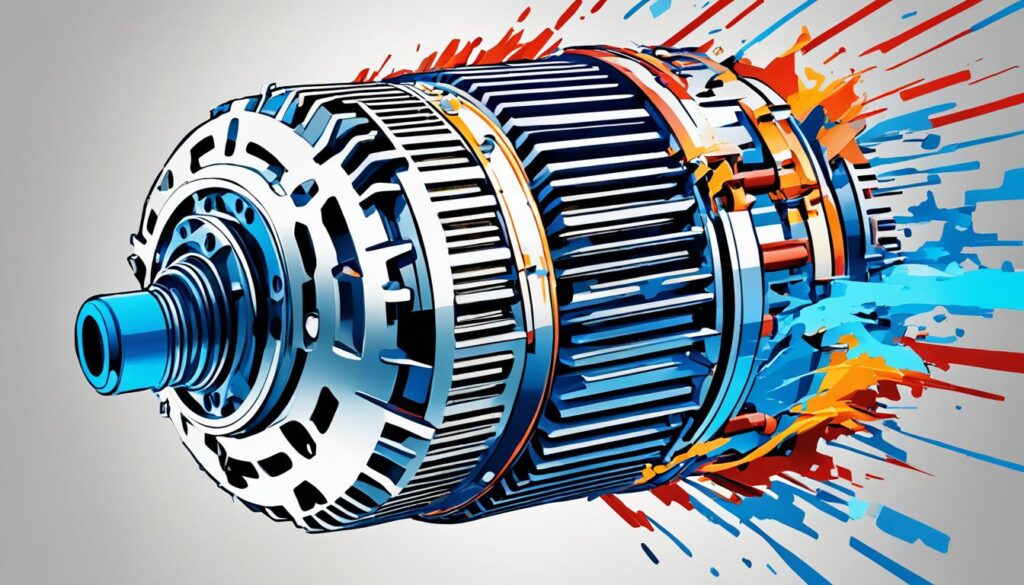

solar power Motor flow is key in motor performance. It’s about air or fluid moving through a motor’s parts. This movement is vital for cooling and removing heat, ensuring the motor works well.

Defining Motor Flow

Motor flow is the speed of air or fluid through a motor’s parts. This includes the rotor, stator, and ventilation system. It’s affected by the motor’s design, how it’s used, and the air or coolant around it.

Importance of Motor Flow

The motor flow concept is very important:

- Cooling: Motor flow helps get rid of heat from the motor’s parts. This stops overheating and keeps the motor running efficiently.

- Efficiency: Good motor flow makes energy transfer better. This boosts the system’s overall efficiency.

- Performance: Enough motor flow keeps the motor at its best. It ensures high torque, speed, and power.

- Durability: Effective motor flow reduces wear on parts. This makes the motor last longer and need less maintenance.

Knowing about motor flow helps engineers and technicians. They can make motors that are reliable, efficient, and last a long time.

FLA and Motor Performance

FLA, or Full Load Amps, is key when talking about motor performance. It shows how much current a motor uses when it’s working at its best. This current is linked to how much power the motor uses, how efficient it is, and how well it performs.

Knowing about FLA helps you figure out if a motor fits your needs. A motor with a high FLA uses more energy, gets hotter, and needs bigger parts. On the other hand, a motor with a low FLA might use less energy but could have less power.

| Metric | Description | Impact on Motor Performance |

|---|---|---|

| FLA (Full Load Amps) | The current drawn by a motor when operating at its rated capacity | Directly related to a motor’s power consumption, efficiency, and overall performance |

By looking at FLA, you can learn a lot about a motor’s performance. This knowledge helps you choose the right motor for your needs. It can also help you save energy and money, and be better for the environment.

“FLA is a crucial metric for evaluating and optimizing motor performance, as it directly relates to a motor’s power consumption and efficiency.”

Next, we’ll talk about what affects motor flow. This is important for understanding how well a motor works.

Factors Affecting Motor Flow

The performance of a motor is influenced by its design and operating conditions. Knowing these elements helps improve air or fluid flow through the motor. This leads to better efficiency and function.

Motor Design

The motor’s design is key to its flow characteristics. The shape of the housing, fan size, and ventilation system all matter. A well-designed motor with good airflow cools better and performs better.

Operating Conditions

Environmental factors like temperature, humidity, and airflow affect the motor’s operation. For instance, high temperatures make the motor work harder, leading to more heat and possible issues. Keeping the motor in the best conditions is vital for steady motor flow and a long life.

| Factor | Impact on Motor Flow |

|---|---|

| Motor Design |

|

| Operating Conditions |

|

Understanding what affects motor flow helps engineers and technicians improve motor performance and efficiency. This is crucial in various applications.

“Effective motor design and proper operating conditions are critical to maintaining optimal motor flow and maximizing the performance of the system.”

Measuring Motor Flow

It’s key to measure motor flow well to check how a motor works and find ways to make it better. Tools like anemometers and flow meters are vital. They help experts measure how much and how fast air or fluid moves through the motor.

When measuring motor flow, picking the right tool is important. Different tools give different levels of accuracy. You need to choose the best one for your motor and job to get good data.

Where you put the tool is also crucial. The spot and how it’s set up can change the results. So, it’s important to plan and place it carefully for accurate data.

| Measurement Technique | Advantages | Limitations |

|---|---|---|

| Anemometer |

|

|

| Flow Meter |

|

|

Using the right motor performance testing tools and methods helps experts understand how well a motor works. They can find ways to make it better. This improves the whole system’s performance.

Optimizing Motor Flow

To get the best out of a motor, you need to look at both its design and how it works. By tweaking these areas, you can make a big difference in how well the motor flows and its overall efficiency.

Design Considerations

The motor’s housing shape, fan size, and ventilation system are key. A smooth housing, the right fan size, and good airflow are all important. They help make the motor flow better.

Operational Adjustments

Changing how the motor works is also crucial. Keeping it clean and checking the environment can help a lot. This way, you can make the motor work more efficiently.

| Design Consideration | Potential Impact on Motor Flow |

|---|---|

| Motor Housing Shape | Streamlined housing can minimize turbulence and improve airflow |

| Fan Size and Design | Properly sized and designed fan can enhance air circulation |

| Ventilation System Efficiency | Effective ventilation promotes efficient heat dissipation and airflow |

“Optimizing motor flow is a critical step in unlocking the full potential of any motor-driven system. By addressing both design and operational factors, organizations can achieve remarkable improvements in efficiency and performance.”

Applications of Motor Flow

Motor flow is key in many industrial areas, like making things and moving goods. It helps make things more efficient, use less energy, and last longer. This is true in many places.

Industrial Applications

Many machines in industries use electric motors. By watching and controlling motor flow, industries gain a lot:

- They can make more and work faster in factories.

- They use less energy and save money in plants.

- Trucks and trains run better and last longer.

In the manufacturing industry, checking motor flow helps make machines work better. This means more stuff gets made and less time is lost. In the processing industry, it helps use less energy and work more efficiently.

The transportation sector also gets better with motor flow analysis. It makes vehicles more reliable and last longer. This means less money spent on fixing things and better service.

“Optimizing motor flow is a game-changer for industries seeking to boost productivity, reduce energy consumption, and extend the service life of their critical equipment.”

As we all want to save energy and make things work better, motor flow analysis will help more. It will be used in many areas, from making things to moving them around.

Challenges in Managing Motor Flow

Managing a motor’s flow can be tricky and affect its performance. It’s key to tackle these issues to keep motors running well and reliably.

Keeping airflow steady is a big challenge. Things like dust, debris, or changes in temperature and humidity can mess with air flow. This can make the motor less efficient and cause problems.

- Ensuring efficient air circulation is essential for optimal motor performance.

- Regularly inspecting and cleaning the motor components can help mitigate the effects of environmental factors.

Another issue is blockages or wear in the motor’s parts. As time goes by, parts can wear out or get clogged. This can block air or coolant flow, hurting the motor’s performance.

- Implementing a proactive maintenance schedule to identify and address any issues early on can help prevent major problems.

- Regularly inspecting and replacing worn or damaged components can ensure smooth and uninterrupted motor flow.

| Challenge | Impact on Motor Flow | Mitigation Strategies |

|---|---|---|

| Environmental Factors | Disruption of air flow, reduced efficiency | Regular inspection and cleaning of motor components |

| Blockages and Wear | Restrictions in air or coolant flow, decreased performance | Proactive maintenance, replacement of worn components |

It’s vital to tackle these challenges to keep motors running at their best. By understanding and addressing these issues, businesses can make their motor-driven systems more efficient and last longer.

Future Trends in Motor Flow Technology

The world is changing fast, and so is motor flow technology. New ideas are coming up to make motors work better and use less energy. These include better motor designs, smart monitoring, and predictive maintenance. These advancements will change how we manage motor flow in the future.

One big trend is in motor design. Scientists are working on designs that use less energy and move better. They use computer simulations to test and improve motor shapes and parts. This could make motors more efficient, saving energy and money.

Smart monitoring systems are also becoming popular. These systems use sensors and computers to watch how motors are doing. They can spot problems early, helping avoid big issues. This means less downtime and more reliable motors.

Predictive maintenance is another important trend. It uses data and smart algorithms to predict when maintenance is needed. This helps plan better and save resources. It also makes motors last longer and work more reliably.

These trends are key to making motors more efficient and reliable. They promise big improvements in many areas, like industry and transportation. This will lead to better performance and savings in the future.

| Future Trend | Key Benefits |

|---|---|

| Advanced Motor Design |

|

| Smart Monitoring Systems |

|

| Predictive Maintenance Solutions |

|

Technology keeps getting better, and so does motor flow technology. These new ideas promise to make motors more efficient and reliable. They will help save energy and money, changing how we power our world.

Conclusion

Understanding motor performance and the role of motor flow is key. It helps improve the efficiency and output of motor systems. By looking into factors like FLA, motor design, and operating conditions, experts can maximize their motor assets.

This leads to better productivity and cost savings. By using detailed measurement and optimization strategies, businesses can fine-tune their motor operations. This ensures they work at their best.

This approach not only boosts motor efficiency but also keeps companies at the top of industry standards. It drives long-term success and sustainability.

As the industry grows, new trends in motor flow technology will open up more opportunities. By keeping up with these advancements and using the latest tools, motor experts can lead their organizations to growth. They will stay ahead in the changing world of motor performance.

FAQ

What is motor flow?

Motor flow is the movement of air or fluid inside a motor. It’s key for cooling the motor and removing heat. This ensures the motor works well.

Why is motor flow important?

Knowing about motor flow helps in making and keeping motors efficient. It keeps the motor cool and running well. This makes the motor last longer and work better.

What is FLA, and how does it relate to motor performance?

FLA, or Full Load Amps, shows how much current a motor uses when it’s fully loaded. It tells us about the motor’s power use and heat. This info helps us see how well the motor is doing.

What factors affect motor flow?

Many things can change how air or fluid moves through a motor. The motor’s design and how it’s used are big factors. Things like the motor’s shape, fan size, and how it’s ventilated matter. Also, the environment around the motor, like temperature and humidity, plays a role.

How can motor flow be measured?

Measuring motor flow accurately is important to check how well a motor is doing. Tools like anemometers and flow meters help measure air or fluid movement. This tells us if the motor is working right.

How can motor flow be optimized?

To get better motor flow, you can tweak the design and how it’s used. Changing the motor’s housing, fan size, and ventilation can help. Also, keeping the motor clean and watching the environment can improve its flow and efficiency.

Where are motor flow applications found in industry?

Motor flow is key in many industrial areas, like making things, processing, and moving goods. Getting motor flow right can make things more efficient, use less energy, and make motors last longer.

What are some challenges in managing motor flow?

Handling motor flow can be tough. It’s hard to keep airflow steady, deal with environmental changes, and fix problems like blockages or wear. Finding and fixing these issues is crucial for good motor performance.

What are the future trends in motor flow technology?

New tech is coming for better motor flow management. We’re seeing better motor designs, smart monitoring, and predictive maintenance. These advancements will help motors work even better and last longer.